The 1650-A was introduced in 1959. It's a solid 1% performer and like most GR products can do slightly better than that if carefully set up. I always have one around in case I need to measure components on a service visit, or sometimes just to teach someone how to use a traditional mechanical bridge. Though it doesn't have the absolute accuracy of the 1608-A or a Digibridge, it's plenty accurate for most projects. It can also match parts to a much higher level of accuracy by noting meter deflection, something useful when constructing stepped attenuators for audio projects or other work where tightly matched components are needed.

The 1650-B was introduced in 1968. The 1650-B adds several features like a conductance range to extend the measurement of high resistance values to 1000 megohms, and access to the bridge arm opposite the unknown via a new jack on the side of the unit. Another goal of the 1650-B was to cut costs. No doubt the original version was getting more expensive to produce and the 1650-B is ever so slightly smaller and lighter. The 1650-B is described in the May 1968 Experimenter; this is well worth the read for descriptions of how to measure the impedance of power supplies, batteries, amplifier inputs and even how to generate parameters for transistor models. Did they even have SPICE models in 1968, or was GR truly clairvoyant?

There are many inexpensive hand held LCR meters that can match or better most of the functions of the 1650 bridges. In all honesty, if all you want to do is confirm component values while building a project, one of those will be faster and less prone to error. I've seen new digital capacitance meters for as little as $34 from electronic flea market vendors. It's only for special measurements that a traditional mechanical bridge shows its true value. With appropriate external oscillators and such, you can make measurements using several hundred volts of excitation. You can measure capacitors with a DC bias voltage. You can measure the stray inductance and capacitance associated with resistors. You can determine which batteries have the lowest impedance. You can obtain a value for unstable impedances like mechanically resonant systems that would confuse a modern digital meter. There is no question that the traditional mechanical bridge still has value in the modern electronics lab.

If you need the extra capabilities of the B version, the issue is settled. If not, I can make at least a weak argument for preferring the A version. The several A versions I've restored have been capable of meeting their accuracy specs no matter how badly they've been abused. Everything about the A version is a bit heavier duty. The A version uses heavy duty ceramic wafer switches, compared to the phenolic switches used in the B.

Both units rely on having an exact value reference capacitor, but the way it's toleranced is a bit different. The 1650-A specifies C1 as 0.0995 to 0.0999 uF. That would be 0.0997 ±0.2%. The 1650-B specifies C1 as 0.1 uF ±0.25%. Thus, the 1650-A is not only toleranced tighter, but can often be padded slightly if necessary. If the 1650-B is on the high side, there's nothing you can do about it. The 1650-B uses what appears to be a wax dipped GR-wound polystyrene, as opposed to the traditional mica cap used in the 1650-A. The several B versions I've restored would typically have capacitance errors just over 1%, not quite meeting their original limit of 1%. The A version used large card wound resistors for the bridge arms. The B version uses mostly off the shelf precision metal films.

The B version is a better looking instrument, but the light colored silkscreened panel and clear plastic knob scales don't hold up as well as the crackle finished and engraved A model when exposed to the rigors of the field and the inevitable careless users. Finally, the B version has to be removed from the case to change the batteries. Since leaky batteries cause so much damage, I prefer to remove the batteries when not in use. This is easier with the external battery cap on the A version. On the downside, some parts of the A version are extremely hard to disassemble for service. All that said, I'd probably go with a clean B version over a beat up A version. Being newer, the B versions will typically have seen less use. OK, I admit it. I have one of each.

This will vary with condition, location and luck. In general I'd never pay more than about $150 for a very clean example of either bridge, regardless of the nonsense you see on eBay. An average price is $70 to $125, and this assumes a complete unit in good condition. The last 1650-A I bought was missing the cover and was a bit rough. I paid $40. That's the one in the photo above. You'll notice that its missing the glue-on GR emblem and I've touched up the photo to hide some chipped paint on the corners. Most 1650-A bridges will be missing the rubber surrounds on the case and panel, as they deteriorate with age. Replacements are probably not hard to get, but I've never bothered. Being newer, the B version will usually have them intact as shown above.

It's best to begin at the beginning. Let's say you've just scored a nice 1650 at the local hamfest and know nothing about its condition. Start by downloading an appropriate manual from BAMA or another source. Clean up the front panel using nothing but water, WD-40 or Armor-All. Any solvents, alcohols or ammonia will damage the front panel on either version of the instrument. On light panel instruments they can remove the lettering in a single swipe. Work on old labels and stickers with hot water on a paper towel and/or the WD-40. When everything is clean, use Armor-All to give the unit a nice sheen. Be sure to polish all the excess Armor-All off with a clean cotton cloth or it will leave streaks and deposits.

Next, remove the case and see what shape the innards are in. Usually things are quite clean, but local battery leakage is common. Use whatever means are necessary to clean up any damage. I've had battery leakage corrode the cases so badly that a die grinder was needed to clean up the surface, followed by sanding and polishing with coarse Scotchbrite. Do a good visual examination of all circuitry, looking for burned resistors, leaky electrolytic capacitors and questionable connections. Look for "technician blight", evidence of previous repairs made by knuckleheads using the wrong parts, damaging PC board traces, rounding off screws and nuts and generally making a mess of things.

Pack some paper towels around the switches to catch any excess, then give them a good squirt of Caig DeOxit. Rotate them several times to distribute the stuff and get the contacts clean. Since the contacts are part of the bridge arms they need to be 100%. Find the ball detent mechanism for each switch and put a bit of instrument grease or Break-Free Teflon oil on the ball. Rotate the switch again to distribute it. All switches and knobs should have a positive feel with no drag or slowness of action. You may have to get a bit of oil into the shaft bearing as well. Avoid all greases from the auto store as they invariably harden with time, creating a much more serious problem than if they hadn't been used at all. Lacking anything else, a bit of Vasoline is usually OK.

Now you can install batteries and begin the check-out and calibration process. There are actually very few adjustments. Calibration mostly involves checking the rheostat adjustments and making sure the knobs are installed at precisely the correct positions.

Follow the procedures in the manual, which contains remarkably detailed and efficient instructions, but I'm also going to give you my take on the adjustment of the DQ knob.

The DQ knob hits a stop on the front panel at about the same point as the low D scale reads zero. It needs to be set such that the resistance of the pot is essentially zero with the knob reading zero on the low D scale. At the same time, the instant the knob starts moving off zero, the pot resistance has to increase. In other words, the wiper of the pot must not be excessively far onto the terminating contact at the end of the windings, or you won't have accuracy at small values of dissipation factor. Going the other way, if the pot resistance can never get quite to zero, you won't get a deep null when balancing capacitors with low losses. It can be somewhat difficult to get the knob at just the right position, but it's worth spending the time on.

You can check the accuracy of the dial by measuring a polystyrene capacitor of almost any value. The dissipation factor of a polystyrene cap is so low that the meter should read exactly zero on the low D scale and it should have a very deep and obvious null. You can check the accuracy of the dial at higher settings using the resistance table in the manual, or by calculating a resistor-capacitor combination and actually measuring it. I use 1000 pF with 7958 ohms in series (use a trimpot) for a DF of exactly 0.05 @ 1kHz. The manual sets the knob using resistance value alone, but I consider the start point and very low dissipation values to be much more important as these are usually used the most. Note that if the bridge is in good shape my method and the factory method should give the same results.

The resistance tables for checking the dials are very similar between the two models, but not identical. I'll start with the DQ dial calibration. The bridge must be set to Cp. Measure the resistance between ground and either bias terminal using a good ohmmeter, 4.5 digits or better. Subtract your lead resistance, or do a 4-terminal measurement if possible. There is a 32 ohm resistor in series with the DQ rheostat so the lowest value you'll see is 32 ohms. Remember that the bias terminals are normally jumpered together and if they're not, that may be why your bridge isn't working!

For the 1650-A:

| 1650-A DQ Dial | Low Value (-3%) | Nominal | High Value (+3%) |

| 50 | 31.04 | 32.00 | 23.96 |

| 20 | exact | 79.50 (adjust dial for exact) | exact |

| 10 | 154.40 | 159.20 | 163.98 |

| 5 | 308.90 | 318.40 | 327.90 |

| 2 | 772.10 | 796.00 | 819.90 |

| 1 | 1544.00 | 1592.00 | 1640.00 |

| 0.5 | 3089.00 | 3184.00 | 3279.00 |

| 0.2 | 7721.00 | 7960.00 | 8199.00 |

| 0.1 | 15440.00 | 15920.00 | 16400.00 |

For the 1650-B:

| 1650-B DQ Dial | Low Value (-3%) | Nominal | High Value (+3%) |

| 50 | 30.94 | 31.90 (some have 32.4 ohms) | 32.86 |

| 20 | exact | 79.70 (adjust dial for exact) | exact |

| 10 | 154.40 | 159.20 | 163.98 |

| 5 | 309.43 | 319.00 | 328.57 |

| 2 | 773.09 | 797.00 | 820.91 |

| 1 | 1544.24 | 1592.00 | 1639.76 |

| 0.5 | 3094.30 | 3190.00 | 3285.70 |

| 0.2 | 7730.90 | 7970.00 | 8209.10 |

| 0.1 | 15442.40 | 15920.00 | 16397.60 |

If the rheostat values are out of spec either the rheostat itself is bad, or for the 1650-A C3 or C8 may be leaky. For the 1650-B it would be C7 or C8. In general, if the rheostat can be set as I describe above the tables, and the values aren't wildly wrong, be content with it. The rheostat can't be repaired and over the years the winding has probably worn somewhat. If the values are erratic that's another story and disassembly and cleaning are in order.

Now we'll do the CRL dial. Set the bridge to Lp for this measurement. If the readings aren't very close to the table, requiring just minor touch-up, refer to the manual for resetting the adjustments.

For the 1650-A:

| 1650-A CRL Dial | Low Value | Nominal | High Value | Cam Adjust Screw |

| 3.6 | 3564 | 3600 | 3636 | 5 |

| 2.2 | 2178 | 2200 | 2222 | 4 |

| 1.3 | 1287 | 1300 | 1313 | 3 |

| .6 | 595 | 600 | 605 | 2 |

| .1 | 95 | 100 | 105 | 1 |

| 5.5 | 5445 | 5500 | 5555 | 6 |

| 8 | 7920 | 8000 | 8080 | 7 |

| 11 | 10890 | 11000 | 11110 | 8 |

For the 1650-B:

| 1650-B CGRL Dial | Low Value | Nominal | High Value | Cam Adjust Screw |

| 2.6 | 2574 | 2600 | 2626 | 5 |

| 1.6 | 1584 | 1600 | 1616 | 4 |

| 1.0 | 990 | 1000 | 1010 | 3 |

| 0.52 | 515 | 520 | 525 | 2 |

| 0.06 | 55 | 60 | 65 | 1 |

| 4.0 | 3960 | 4000 | 4040 | 6 |

| 6.5 | 6435 | 6500 | 6565 | 7 |

| 10.0 | 9900 | 10000 | 10100 | 8 |

Most bridges require little more than cleaning and the above touch-up to the calibration. Good ohmmeters are more readily available today than ever, so you can expect to do as good a calibration as any lab. If however, you do suspect problems with other components, and if you have access to the necessary plethora of accurate standards, the following table will help you isolate which bridge arm component is defective.

| Measurement | Standard | Bridge Circuit | Range Setting | Faulty Component |

| A | 1 ohm | Rac | 100 mohm | R5 |

| B | 1 ohm | Rac | 1 ohm | R6 |

| C | 100 ohm | Rac | 10 ohm | R7 |

| D | 100 ohms | Rac | 100 ohms | R8 |

| E | 10 kohms | Rac | 1 kohm | R10 |

| F | 10 kohms | Rac | 10 kohms | R11 |

| G (A ver.) | 1 Mohm | Rac | 100 kohm | R14 and R12 + R13 |

| G (B ver.) | 1 Mohm | Rac | 100 kohm | R13 |

| H (A ver.) | 1 Mohm | Rac | 1 Mohm | R14 |

| H (B ver.) | 0.1 uF | Cs | 100 nF | both C1 and R9 |

| I (A ver.) | 0.1 uF | Cs | 100 nF | both C1 and R9 |

| I (B ver.) | 0.1 uF | Cs | 1 uF | R9 |

| J (A ver.) | 0.1 uF | Cs | 1 uF | R9 |

The manual will give a more complete explanation of faults if multiple errors are encountered.

The 1650 bridges don't draw a huge amount of current so there's no requirement to use alkaline batteries. The construction and chemistry of alkaline batteries makes leakage and instrument damage almost a certainty if the batteries are allowed to fully discharge. Even without full discharge the risk is quite high over time. It's my belief that "heavy duty" carbon-zinc cells, though they can leak as well, tend to take longer and be slightly less damaging, and are a better choice in any device that doesn't require high currents.

The Orthonull feature was Henry P. Hall's first patent. To avoid the dreaded "sliding null" when measuring components with high losses, the Orthonull feature locks the DQ dial to the CRL dial with a friction clutch. If properly adjusted, turning the CRL dial will also turn the DQ dial. But, turning the DQ dial will not turn the CRL dial. The manual describes the feature in detail, but because I didn't grasp it at first, I'll say it again. Using Orthonull, the DQ dial turns by itself in the usual fashion. The CRL dial will also drive the DQ dial at the same time. Balance the bridge in the usual way for the deepest null. Friction will be a bit higher, but the sliding null problem will be entirely avoided, thanks to Henry's very clever invention.

It appears to be common that the 1650-A will read too high on dissipation factor when the oscillator amplitude is turned down to about 1/8 or less of maximum. Reports vary on the size of the error, but my unit would measure about 10X too high, 0.013 instead of 0.0013 with a 5 uF film cap and minimum amplitude. The error can be reduced by half, at least on my unit, by shielding one of the transformer leads. The effectiveness may vary, depending on lead routing and possibly even the phase that the transformer was wired; different users have reported different degrees and symptoms of the problem. Note the new ground lug added to the transformer screw.

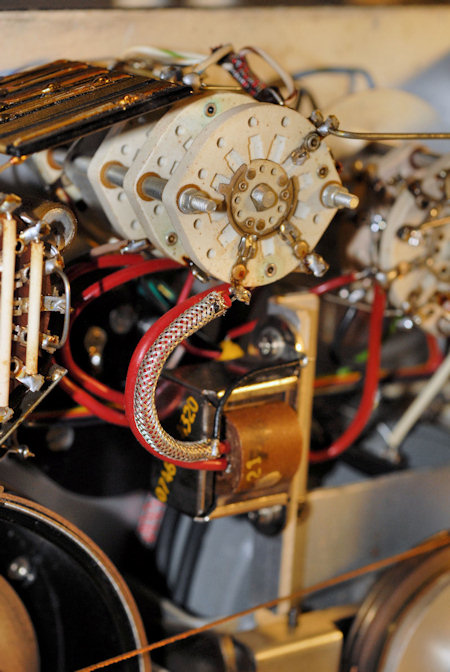

The level pot is 2500 ohms, but it seems to start softly. That first 1/8 turn only covers about 3 ohms. The complete solution is to apply the shielding above, and then add about 5 ohms in series with the pot. That keeps one out of the troublesome area. I didn't have 5 ohms and used a couple 10 ohm parts in parallel. The easiest way to do this is to remove the side of the instrument, just a few screws. Leave the main cap attached to the panel, remove the screw from the lug you can get at and desolder the buss wire from the other lug. Set the panel aside, taking care not to lose the two floating nuts that secure the back cover of the instrument. Now you have good access to the level pot. The photo could show things a bit better but the new resistor is not involved with the cap and solder joint behind it, which are on the circuit board.

After the mod my unit adjusted from 25 mV to 0.74 V across a 1000 pF test capacitor, which seems like a perfectly reasonable range, and with almost no dissipation factor error regardless of the setting.

C. Hoffman

last edit August 22, 2015