The widely available service manual for the CR-620 appears to omit many of the usual FM alignment steps. Other CR series service manuals are more complete, but still inexplicably omit certain RF peaking adjustments. This page is an attempt to better document how to align the CR-620. CAVEAT: this page could have errors or your version of the receiver could be slightly different. You assume all responsibility for anything that gets messed up, be it your fault or mine.

Two important points: 1) you'll need an FM stereo alignment generator with low distortion, a distortion analyzer and a frequency counter. There is no good substitute or work-around for the first, but you may find a PC sound card and software will do nicely for the distortion analyzer, frequency counter and oscilloscope. The free program Visual Analyser is recommended. 2) FM alignment is a bit of an art and just having the necessary equipment won't insure success. If you don't have the equipment and at least some knowledge of how to use it, STOP HERE! Random twiddling with adjustments is more likely to turn your receiver into a doorstop, than to improve anything. At the end of this page, I do note a few things that can be touched up using broadcast signals, but it's not the best method.

I got my CR-620 as a discard, but it worked well and appeared to be reasonably well aligned. It passed the usual bench tests with flying colors. Yamaha receivers have a reputation for very clean sound, but I have to admit I didn't think the FM sounded as good as my Sansui or Marantz receivers, not to mention my dedicated tuners. It was fatiguing to listen to, though I could never put my finger on exactly what was wrong with the sound.

My goal in acquiring free or near-to-free receivers has been to learn alignment techniques for different types of circuits. It's something that requires study and practice to develop reasonable skill, and in all honesty I'm not entirely there yet. Still, the CR-620 was an eye-opener. In spite of appearing to work well when I got it, a proper alignment brought out the sound quality that had previously been missing. It became smooth and sweet, probably because a proper alignment improved the signal to noise and reduced the distortion by a large amount.

Since I first put up this page, another 620 presented itself for alignment and upgrades. It confirmed that the electrolytic capacitors in the 620 have not aged well, and my guess is all 620s, and probably all similar Yamaha receivers from the same time period, need service before an alignment should be contemplated. Though originally an alignment guide, I've added what I hope will be useful service information at the end of the document. You should review that before starting an alignment.

All adjustments need to be made in the absence of undesired signals. For example, if the procedure says to use 98 MHz, and there's a station there, find a quiet spot on the dial close to 98 MHz and use that frequency instead. You may find that only certain times of day lend themselves to doing a good clean alignment.

All RF peaking adjustments need to be made with as small a signal as possible, right down into the noise. If the signal looks good on the scope, it's too large! All other adjustments, especially distortion, can be done with larger signals. Precise signal levels are not required, save for meter calibration. If you use the speaker outputs to look at the signal (you could use tape out), be sure to turn up the volume to about 3 VRMS output, or the distortion measurements will be contaminated by noise.

If the signal doesn't specify modulation, it's a pure waveform available from any signal generator that covers the range and level desired. In that case there will be no audio; in any case, always use the tuning indicator to be sure you're tuned correctly. That's why adjustment of the tuning indicator is step 1. If modulation is specified, you need a stereo FM generator designed for FM alignments. As said above, levels are not critical, only that peaking be done near the noise floor, and that distortion be done at a high enough level so that noise doesn't contaminate the measurement.

If your distortion analyzer has an output to view the distortion residual, you should monitor that on a scope. It's far easier to minimize the harmonic waveform on the scope because you can pick it out from the noise, rather than using the meter or digital readout which, because it sees the noise, will be reading too high. The suggested 17 kHz low pass filter should help, but I haven't built or tried one. The CR-620, unlike some other CR models (CR-820), doesn't have adjustments to fully null the 19 kHz pilot tone.

One on-going alignment mystery is the best way to couple the signal generator to the tuner. Ideally, the signal generator would have a 75 ohm output, plus an excellent attenuator, and would just connect directly to the 75 ohm input of the tuner. That's almost never the case. Since all alignment on the CR-620 is done via the antenna terminals, a common 75-300 ohm balun will suffice. If the generator output is too large for the peaking adjustments, an attenuation pad will be needed between the generator and balun.

Note that the CR-620 local oscillator has the usual compression trimmer (TC3) for the top end, but only an air coil for the lower end. It is best never to touch the air coil as adjustment is difficult and the coil is locked with paint. Thus, the lower end is best allowed to fall where it may, assuming it's close, with the dial cord set per the manual (at the left mark).

Use only correctly fitting plastic alignment tools. Carve your own out of hard wood or plastic if you have to. Never use metal tools of any sort or you'll chip and break irreplaceable slugs. The tools will also detune the circuit and give you a bad alignment. The antenna core (AM alignment) may not be adjustable as some seem to be glued in place. Don't force it!

The service manual specifies signal voltage in dBuV. Your signal generator may be calibrated in dBm, which is power, most likely into 50 ohms. 60 dBuV = -47 dBm into 50 ohms. 80 dBuV = -27 dBm into 50 ohms. You have to include balun and pad losses, if present. As said previously, levels are not critical unless you want an accurate signal strength meter calibration. The service manual also has some labeling confusion between the schematic, parts list and board silkscreen, but the meaning should be obvious, whether they say TC1 or CT1. The board may be silkscreened with the actual function, like "DIST".

Before beginning the alignment procedure, check your dial cord for proper tension. The spring inside the pulley should have at least some space between the coils. If the spring has gone solid, the dial cord tension will be too low and it may slip on the tuning knob shaft. My dial cord had stretched enough that the spring went solid, plus it was painted to the pulley where it should have been able to slide freely. Worse, the pulley shaft that's supposed to be press fit to its gear, came out, something that's a bit of a nightmare to reassemble. Never pull on the pulley! Fixing that problem is far beyond the scope of this page, but if it happens, there's a good post with pictures showing how to fix it on audiokarma.org. If your dial cord system needs restringing or attention, it's best to take care of that before alignment.

It's very easy to get the dial cord hung up on the upper cabinet bracket when reassembling the unit. Put the pointer off center and watch carefully that the cord clears the bracket on reassembly.

The CR-620 is quite easy to align because there's no fussy IF bandpass to adjust. It uses three fixed response ceramic resonators instead. Refer to the service manual for most adjustment names and locations, some of which are also silkscreened on the PCB.

| Step | Description | Adjust | Input | Signal | Procedure |

| 1 | Discriminator balance | T101, top core | none | none | Check that the tuning meter reads zero with the power off. Power up. Tune to a quiet spot near 98 MHz and adjust the top slug only of T101 so the tuning meter is exactly centered. Use a magnifying glass. It may help to short all antenna terminals to ground. |

| 2 | Pointer | Location on cord | FM Ant. | 88 MHz, 60 dBu | Tune to signal (tuning meter centered) and position pointer at 88 MHz on dial cord. If it's within 2 mm, don't adjust. |

| 3 | Local Oscillator (LO) | TC3 | FM Ant. | 108 MHz, 60 dBu | Tune to 108 MHz on dial and adjust TC3 for maximum signal (tuning meter centered). If you can tune the signal within 2 mm on the dial, don't adjust. |

| 4 | Repeat above | Pointer & TC3 | FM Ant. | 88-108 MHz, 60 dBu | Adjust pointer location and TC3 to achieve 2 mm accuracy over dial. |

| 5 | Peak RF signal | TC1 & TC2 | FM Ant. | 108 MHz, L+R 1 kHz 100% mod. | Tune to signal (tuning meter centered) and monitor audio output with scope. Reduce amplitude so signal is just above noise (receiver in mono). Adjust TC1 & TC2 to maximize signal. Noise should be breaking signal equally on top and bottom. |

| 6 | VCO free run | VR201 (VCO) | FM Ant. | 100 MHz, L+R 1 kHz 100% mod., 60 dBu no pilot tone | Stereo mode- Monitor VCO test point with a frequency counter (use 10X probe to prevent loading) and adjust VR201 (VCO) for 18980-19020 Hz. Pot is very sensitive. |

| 7 | L+R THD | T101, bottom core | FM Ant. | 100 MHz, 60 dBu, L+R 1 kHz 100% mod. | Tune to signal (tuning meter centered). Monitor left output with THD analyzer and adjust lower slug only of T101 for minimum distortion. Use a 17 kHz low pass filter if available. |

| 8 | L THD | IFT & DIST trimpot | FM Ant. | As above, L only. | Adjust IFT and the DIST trimpot (behind the tuning block) for minimum distortion. The final result should be better than 0.25% |

| 9 | Separation | SEP1 & SEP2 | FM Ant. | As above, L or R | Monitor both outputs on a scope or meter. Adjust SEP1 and SEP2 for maximum separation when switching between L and R on the generator. This is mostly adjusting for a null on the zero signal channel so turn the meter or scope gain up. |

| 10 | Signal meter calibration | VR301 | FM Ant. | 98 MHz, 80 dBu | Tune to generator (tuning meter centered) and adjust VR301 for a reading of 90 on the signal strength meter. Not a critical adjustment if you don't have a calibrated generator. |

If the tuner was badly out of alignment it's a good idea to repeat the procedure as there may be some interactions between the adjustments. When you're finished, assuming you don't have multipath problems in your location, and with non-competing signals, the tuner should show maximum signal strength at the same point as the tuning meter is centered, along with the cleanest strong stereo sound. Going off center, noise and loss of stereo should happen more or less equally on both sides of zero.

It should be obvious that you need the right equipment to do a successful alignment, however there are a few things that can be touched up using only broadcast signals. The tuning meter can be zeroed between stations. The dial calibration can be set using stations at the low and high end of the band. The RF could be peaked up using very weak signals at the high end of the band. The VCO could be adjusted for a clean lock using very weak stations. As for the rest, disturbing the adjustments without test equipment will lead to nothing but trouble.

The service manual AM alignment procedure is reasonably good. No modulation is needed and the entire thing can be done with a good function generator that can sweep, and a counter.

| 1 | 455 kHz IF | CF401 (small oblong transformer with off-center adjustment) | Ferrite bar antenna | Slow sweep around 455 kHz at low amplitude | Set pointer to low end of dial, adjust for maximum peak height (audio output) regardless of frequency. |

| 2 | Local Oscillator (LO), low end | T401, a.k.a. GE6013 | Ferrite bar antenna | 600 kHz, 80-100 dB/m | Set pointer to 600 kHz on dial, adjust for maximum meter deflection. |

| 3 | Low end sensitivity | Ferrite bar antenna core | Ferrite bar antenna | 600 kHz, 60 dB/m | Set pointer to 600 kHz on dial, adjust for maximum meter deflection. It may be glued in place- do not force. |

| 4 | Local Oscillator (LO), high end | CT0 | Ferrite bar antenna | 1350 kHz, 80-100 dB/m | Set pointer to 1350 kHz on dial, adjust for maximum meter deflection. |

| 5 | High end sensitivity | TCA | Ferrite bar antenna | 1350 kHz, 60 dB/m | Set pointer to 1350 kHz on dial, adjust for maximum meter deflection. |

| 6 | Repeat adjustments | Ferrite bar antenna | 600 & 1350 kHz, 60 dB/m | Repeat adjustments 2-3 times to minimize tracking error and sensitivity over full range. | |

| 7 | Confirm midrange | Ferrite bar antenna | 950 kHz, 80-100 dB/m | Tune to 950 kHz and confirm that pointer is within 2 mm of 950 on the dial. |

After testing several units, all had significant numbers of below-value capacitors in the power and tone sections of the circuit. The tuners seemed to fare better, but don't waste time aligning the tuners to the Nth degree before measuring and replacing any bad capacitors. Almost all can be checked in-circuit and the only problem found was low capacitance, not DC leakage or high dissipation factor. Replacing all of them is highly recommended.

Just to give you an idea of how badly the particular caps used in the 620 have aged, here's a table with measurements of all the electrolytic capacitors on a tone board. These are series measurements at 120 Hz taken after the caps were removed. The DC leakage is at rated voltage, T = 2 minutes, and expressed in terms of CV. Most common capacitors are rated at 0.01 CV.

| Marked | Cs | D | Leakage, CV |

| 100/16 | 29.5 | 0.105 | 0.0125 |

| 100/16 | 34 | 0.123 | 0.0075 |

| 100/10 | 38.4 | 0.148 | 0.06 |

| 100/10 | 31.2 | 0.145 | 0.025 |

| 47/16 | 11.5 | 0.123 | 0.0013 |

| 47/16 | 11.9 | 0.118 | 0.0013 |

| 47/6.3 | 56.3 | 0.164 | 0.0084 |

| 47/6.3 | 63 | 0.145 | 0.0034 |

| 10/35 | 12 | 0.044 | 0.011 |

| 10/16 | 5.2 | 0.144 | 0.063 |

| 10/16 | 4.7 | 0.157 | 0.063 |

The values are mostly low but none of the caps were out of spec for dissipation factor. The full voltage DC leakage test is quite unfair, as the caps have spent decades at voltages well below their ratings, yet only three caps showed high leakage. After some time under voltage to reform, they'll probably come down to the datasheet limits, though they probably won't come down to new cap values. The parts with higher capacitance values suggest internal changes and should also be replaced.

An ESR meter probably won't find any bad parts in the 620, only a capacitance bridge or meter that measures value. Almost all of the caps can be tested in-circuit if the test voltage is low. Regardless, the sheer number of below-value parts dictates that every single electrolytic in the unit be replaced. Modern capacitors don't have any problems operating well below their ratings, and parts between 25 and 63 volts tend to have better properties. For that reason, and because new parts are smaller, I will typically use 25 and 50 volt parts in most locations.

The main filter caps and many caps on the power board were also bad on both units serviced. The locations tended to be common to both units, suggesting a systematic problem with certain cap types. New parts are inexpensive; your main investment will be time, but the improvement in sound quality will be well worth the effort.

A hint- if you photograph the top of the board you can mirror it in any imaging program. Print it out and it will make identifying the cap locations from the bottom much easier. This prevents having to constantly flip the unit or flex wires to identify the correct solder joints.

You'll have to pull the front panel to remove the tone board. Follow the commonly available service manual. There's a plate over the power switch that has to be removed (2 screws) to free the tone board. That's also the time to use some DeOxit on the treble, bass and loudness pots, which are otherwise hard to get to.

Though any device in the signal chain can become noisy, I've seen several instances of TR671 and 672 becoming noisy. Many small signal NPN devices will work fine in that location. I used 2SC945 because the curves matched and I had a good supply of them.

Immediately after TR671/2 is the balance control. This loads down whichever channel needs to be cut, but it also changes the time constant against the associated coupling capacitor. The result is that using the balance control also rolls off the low frequency response of the channel being cut, about -3 dB at 20 Hz for a moderate cut. The output coupling caps are a bandwidth bottleneck and using 10 uF for both input and output seems a better choice, especially when you consider they used 47 uF downstream for the power amp input.

There is a slight layout error with the power supply grounds that may or may not be an issue. If you have a very slight hum or buzz under zero volume conditions with headphones, probably worse after new caps are installed, you may want to try this fix. D809 (the number on my schematic is blurred, but it's the lone diode near the center of the transformer cover next to a power resistor) connects to a "quiet" ground trace, injecting a small amount of ripple. There is an associated 100 uF capacitor that's probably low in value, reducing the problem a bit. After replacing the bad capacitor, the current will be back to normal, and the hum level will increase slightly.

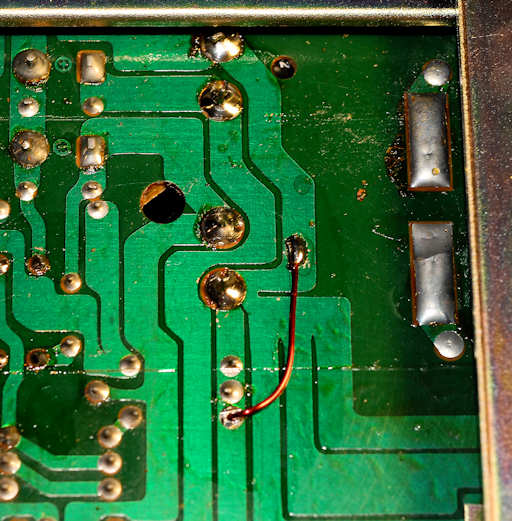

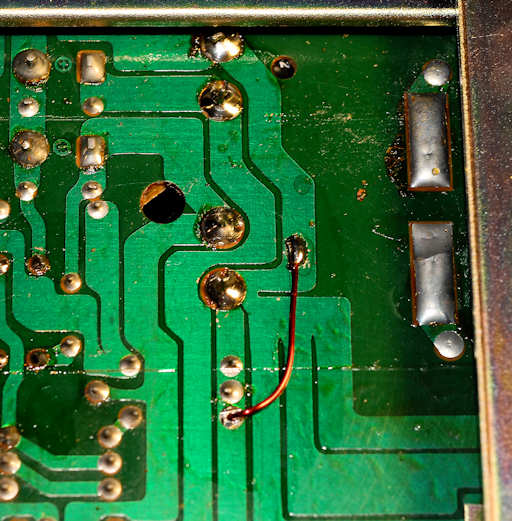

The ground connection of the diode should be unsoldered and an insulated wire (I used heavy enameled wire) brought through the hole and attached to the lead. This wire is then bent over on the bottom of the board and attached to the "dirty" ground between the main rectifiers and the the star ground point. Scrape away a bit of the solder mask to make the connection. You're connecting the diode to the same trace, but on the other side of the filter cap pin. The wire could also just be brought around the board edge if desired. The mod kills the hum and does no harm but I still have some reservations because it's hard to believe Yamaha would have shipped a design with audible hum, even if at a very low level. To date I haven't found any other ground connection that would swamp out the error. Be sure the screws at the board mounting points are snug, as the chassis connects to ground at those points. Here's a photo of the fix.

To summarize, replace all electrolytics with new parts having at least the voltage ratings of the original parts, but no lower than 25 V. Increase the value of the TR671/2 output cap to 10 uF. I use a 50 V part for both input and output for the improved dissipation factor and linearity. Reconnect the diode ground as described above. Insure that all circuit board mounting/ground screws are snug. Do your FM and AM alignments. I think you'll be surprised at just how good the CR-620 can be.

C. Hoffman

April 27, 2014

Last edit September 27, 2015